4-inch Nanofabrication Facility with CMOS & MEMS capabilities

At STNF, you can build your own readout integrated circuit

(ROIC) with 500 nm

technology nodes around your exiting invention or idea.

Our sensor foundry services

for ROIC/CMOS processes start at US$ 35K for one batch and

customers can reduce

the cost per wafer as they increase the batch size

At our 4-inch nanofabrication facility, we offer a

comprehensive range of wafer

fabrication processes- from Lithography, Etchning, Ashing,

to Chemical Mechanical

Polishing (CMP). Specializing in 4" wafers, we can also

process 4" downsized wafers

obtained via wafer coring. Striving to be a one-stop

solution provider, we also offer

PCB wire bonding services and keep a Scanning Electron

Microscope (SEM) available to

inspect customer samples.

The STNF team boasts a combined experience of 20+ years in

fabricating micro and nano

technologies in both CMOS and MEMS. Our journey began

within the walls of the Stanford

Nanofabrication Facility (SNF) and is now continuing at

our own in-house fab in San Jose.

As a consultant for SNF, we also provide consultation

services for device fabrication

as well as seamless transition into and out of working

with SNF.

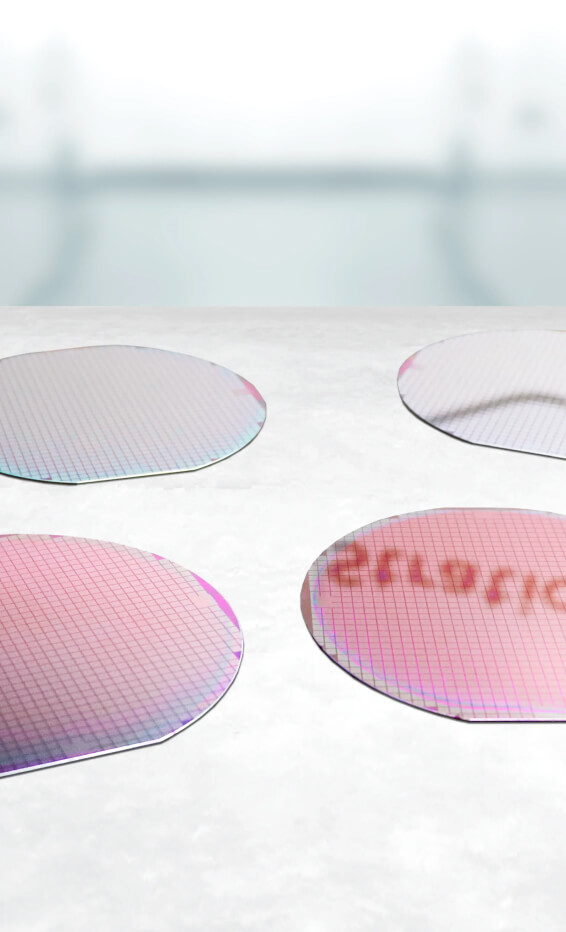

At STNF, you can build your own readout integrated circuit (ROIC) with 500 nm technology nodes around your exiting invention or idea. Our sensor foundry services for ROIC/CMOS processes start at US$ 35K for one batch and customers can reduce the cost per wafer as they increase the batch size

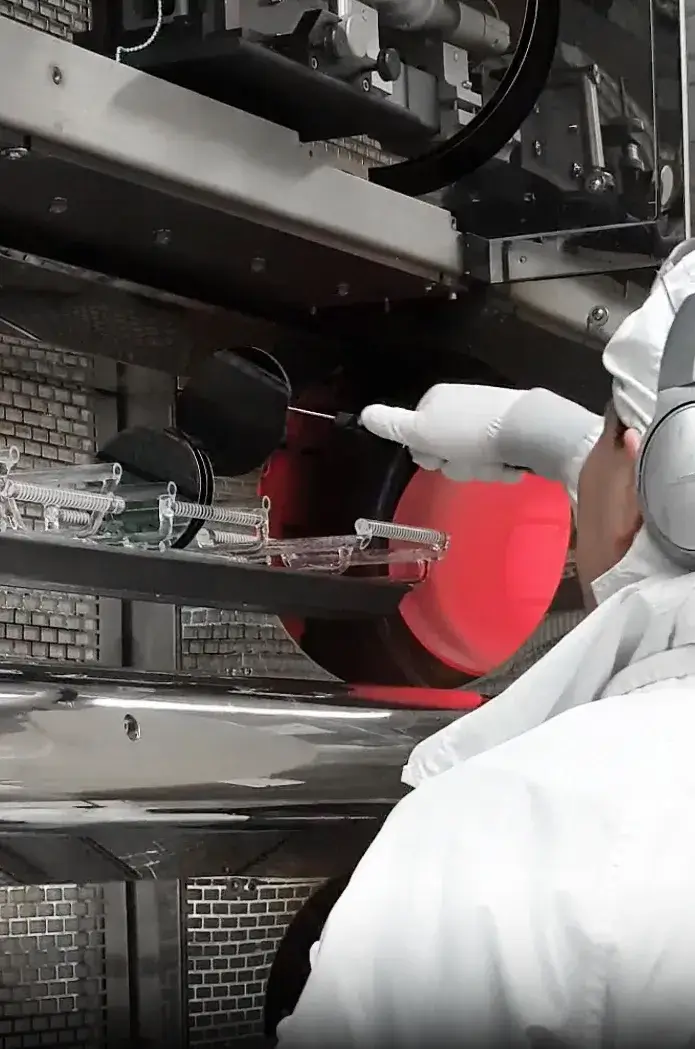

At our 4-inch nanofabrication facility, we offer a comprehensive range of wafer fabrication processes- from Lithography, Etchning, Ashing, to Chemical Mechanical Polishing (CMP). Specializing in 4" wafers, we can also process 4" downsized wafers obtained via wafer coring. Striving to be a one-stop solution provider, we also offer PCB wire bonding services and keep a Scanning Electron Microscope (SEM) available to inspect customer samples.

The STNF team boasts a combined experience of 20+ years in fabricating micro and nano technologies in both CMOS and MEMS. Our journey began within the walls of the Stanford Nanofabrication Facility (SNF) and is now continuing at our own in-house fab in San Jose. As a consultant for SNF, we also provide consultation services for device fabrication as well as seamless transition into and out of working with SNF.

At our 4 inch nanofabrication facility, a comprehensive

range

of wafer fabrication processes is at your service - from

Lithography,

Etchning, Ashing, to Chemical Mechanical Polishing

(CMP).

Specialized in 4" wafers, we can also process 4" downsized

wafers

obtained via wafer coring. Striving to be a one-stop

solution provider,

we also offer PCB wire bonding services and keep a

Scanning Electron Microscope (SEM)

available to inspect your samples.

The STNF team has a combined experience of 20 years in

fabricating

micro and nano technologies, beginning from within

the walls

of Stanford Nanofabrication Facility (SNF)

and now

continuing in San Jose at our in-house fab.

As a consultant of SNF, we also provide consultation

services

for device fabrication as well as seamless transition

into and out of SNF.

Chosen by

We Care About Our Customers

HISTORY

STNF was created by STRATIO, INC. as a part of our journey

to bring infrared

vision to the mass market through our smart infrared

devices LinkSquare® and

BeyonSense®. Originating from our experience in building

these novel devices

with in-house resources, STNF has acquired its own

cleanroom facilities to

ensure control over quality and efficiency in production.

STNF, a 4" fab in the San Francisco Bay area, was first

opened to the public

in 2020. This facility was designed to support the

development of our own

innovations as well as serve as a starting point for

others. Today we strive

to help others bring their own innovative ideas to

fruition and enable a better

world for the future.

HISTORY

The Stratio Technology Nanofabrication Facility (STNF)

is in San Jose, California, in proximity

to the

Stanford Nanofabrication Facility (SNF).

We are proud to be a part of the semiconductor tradition

at the heart of Silicon Valley and to carry

on the history of "made in California".